jominy hardness test|jominy steel hardenability test : purchasing • In this lab, we’re working to evaluate how three types of steel—1045, 4340, and 6150—differ in hardenability. Since these steels have similar carbon content, we can look more closely at how other alloying elements like chromium and manganese influence hardness and structure. • The Jominy end-quench test will let us measure hardness along each sample, .

SAP are automatic pressure control autoclaves. Its advantage lies in its product line diversity .This series represents the entry-level model of microcomputer-controlled Class B autoclaves, .

{plog:ftitle_list}

This is a new autoclave engineered and fabricated by Taricco Corporation. Designed to meet the advanced requirements of the composite bonding aerospace and racing industries, this .

The Jominy end quench test [1] [2] (ASTM A255 [3]) is an extremely simple and useful test that is applicable to many materials besides steel [4] [5]. This test can provide basic information on the hardenability of a material and be used for specifying incoming material for .Learn how to measure hardenability of steel using the Jominy End-Quench Test, a .

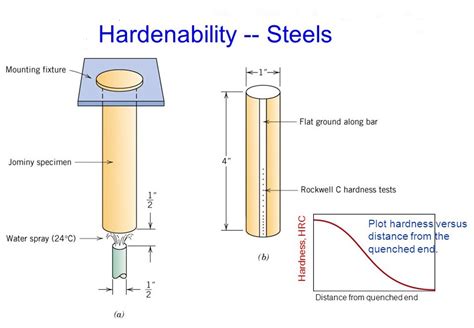

Key Words: Hardness, Hardenability, Jominy test, Quench, Steel Type of Module: PowerPoint presentation with discussion and lab or in-class demonstration depending on availability of equipment Time required: two 50 min sessions if the lab is undertaken; one session for the in-class presentation Suggested prerequisite MatEdu modules: 1. Vickers Hardness; Rockwell Hardness; A plain carbon steel and an alloy steel were assessed using the Jominy end quench test. The hardness of the samples was measured as a function of the distance from the quenched end to demonstrate the different hardenability of the two steels. The data is shown as Vickers and Rockwell hardness.Jominy test dimensioning Jominy test apparatus Used Jominy test-piece. Hardenability is the depth to which a steel is hardened after putting it through a heat treatment process. It should not be confused with hardness, which is a measure of a sample's resistance to indentation or scratching. [1] It is an important property for welding, since it is inversely proportional to .

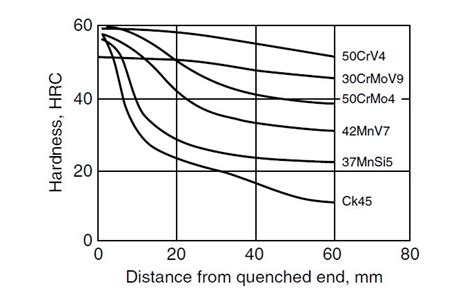

• In this lab, we’re working to evaluate how three types of steel—1045, 4340, and 6150—differ in hardenability. Since these steels have similar carbon content, we can look more closely at how other alloying elements like chromium and manganese influence hardness and structure. • The Jominy end-quench test will let us measure hardness along each sample, . In order for phase transformation to occur in all parts of the material, then the cooling process is carried out using the Jominy test, showing the mechanical strength, namely the Vickers hardness . The Jominy end quench test is the standard method for measuring the hardenability of steels. This describes the ability of the steel to be hardened in depth by quenching. Hardenability depends on the chemical composition of the steel and also be can affected by prior processing conditions, such as the austenitizing temperature.

3.1 This test method covers the procedure for determining the hardenability of steel by the end-quench or Jominy test. The test consists of water quenching one end of a cylindrical test specimen 1.0 in. in diameter and measuring the hardening response as a function of the distance from the quenched end.JOMINY HARDENABILITY TEST Objective . The dependence of hardness upon quenching rate can be understood ftom the time-temperature-transformation characteristics of steel, and, for a particular steel, can be estimated from the T-T-T diagram. A part may be hardened by quenching into water, oil, or other suitable medium. The surfaceHardenability can be measured using the Jominy end quench test. Jominy end quench test. The test sample is a cylinder with a length of 102 mm (4 inches) and a diameter of 25.4 mm (1 inch). Jominy test specimen. The steel sample is normalised to eliminate differences in microstructure due to previous forging, and then austenitised. This is .

Data from the Jominy end quench test can be used to determine whether a particular steel can be sufficiently hardened in different quenching media, for different section diameters. . Carbon controls the hardness of the martensite. Increasing the carbon content increases the hardness of steels up to about 0.6wt%. At higher carbon levels, the .

the jominy end quench test

Sifat kekerasan (hardness) suatu logam merupakan salah satu persyaratan utama di dalam pemilihan suatu elemen mesin. Kekerasan suatu logam, baja khususnya, dapat dimodifikasi tanpa menambahkan unsur . pengujian Jominy Test ini dilakukan di workshop Teknik Mesin Fakultas Teknik Universitas 45 Bekasi Gambar 4.1 Standar ASTM A 255 Rockwell Hardness Testing Machine Procedure: 1. Preheat the furnace to 1700 oF. 2. Place the Jominy specimen in the furnace and soak for one hour. 3. Turn the water on at the Jominy sink. . In the Jominy test the quenching medium is eliminated from consideration by standardizing the effect of the quenching medium on a steel sampleThe Jominy test provides valid data for steels having an ideal diameter from about 25 to 150 mm (1 to 6 in.). This test can be used for D I values less than 25 mm (1 in.) but Vickers or microhardness tests must be used to obtain readings that are closer to the quenched end of the bar and closer together than generally possible using the standard Rockwell ‘C’ hardness test .ISO 6507-1, Metallic materials — Vickers hardness test — Part 1: Test method [2] ISO 6508-1, Metallic materials — Rockwell hardness test — Part 1: Test method [3] JOMINY, W.E., Standardization of Hardenability Tests, Metal Progress, Vol. 40, December 1941, pp. 911-914. [4]

Rockwell is often used as a quick test in production or in the laboratory, as well as for other processes, such as the Jominy end quench test / Jominy test. The most common Rockwell method in practice is HRC. In principle, ball indenters are used for the hardness tests on softer materials and diamond indenters for testing harder materials. The .Jominy test, juga disebut sebagai Jominy end quench test, adalah metode standar menurut ISO 642 dan ASTM A255 untuk penentuan hardenability baja. Hardenability adalah kemampuan baja untuk meningkatkan kekerasan secara .

Fig.4: Equivalent Jominy positions and bar diameter, where the cooling rate for the bar center is the same as that for the point in the Jominy specimen. For example, if the hardness at the center of a 5 cm diameter bar, quenched in still .

Thermal Engineering of Steel Alloy Systems. T. Inoue, in Comprehensive Materials Processing, 2014 12.06.7 Jominy End Quenching 12.06.7.1 Jominy Test. The Jominy test, or Jominy end quench test, is known to evaluate the hardenability of steel in a simple way (64).The basic idea of the test and also the data obtained are used to understand the effects of alloying . This page titled 35: The Jominy End Quench Test is shared under a CC BY-NC-SA 2.0 license and was authored, remixed, and/or curated by Dissemination of IT for the Promotion of Materials Science (DoITPoMS) via source content that was edited to the style and standards of the LibreTexts platform. Jominy end quench hardenability test - Download as a PDF or view online for free . The hardness is measured at intervals along its length beginning at the quenched end. For alloyed steels an interval of 1.5mm is commonly used where as with carbon steels an interval of .75mm is typically employed. 7.The Jominy test (End Quench Test) is a standardized test procedure used to determine the hardenability of steel, and it can be performed using any Vickers micro hardness tester. The procedure is described in the following standards: ASTM A255 / ISO 642 / DIN 50191 / BS 4437

the use of the Jominy end quench test will be described. The hardness machines. It is also necessary to ensure that the speci-previous use of the Jominy end quench test for nonferrous men is in a fixture that ensures accurate positioning and firmly alloys will be discussed, and the specific use of the Jominy holds the specimen. It was found .The Jominy test, also known as the End-quench test, is a standardised method for determining the hardenability of steel in accordance with ISO 642 and ASTM A255. The hardenability describes the ability of the steel to increase the hardness at the surface or throughout the workpiece by forming martensite or bainite.One of the hardenability testing methods is the Jominy Test. The specimen is heated at the specified temperature, then cooled by spraying water at one end. After testing with the Jominy test apparatus, its hardness was measured using the hardness test equipment.The testing of Jominy is based on ASTM standard A255. Testing using specimens with a .Suntec's Jominy fixtures are essential tools for precise hardness testing. Trust our high-quality fixtures for reliable and consistent Jominy end-quench testing, ensuring accurate material analysis results and facilitating research in metallurgy and heat treatment. . Jominy Fixture provides end quench testing, meeting ASTM A 255 which is the .

©ISO ISO 642:1999(E) 3 5.2 Dimensions 5.2.1 The test piece shall consist of a round bar machined to a diameter of 25 mm and a length of 100 mm. 5.2.2 The end of the test piece which will not be quenched shall be 30 mm to 32 mm or 25 mm in diameter,Newage Jominy fixtures are for use with most Indentron, Versitron or ME-2 Series hardness testing systems. This test fixture is designed to hold standard Jominy test samples for conducting Jominy H-band test configurations.

jominy value

Cool before touching to living material by dipping in sterile water or by touching to the edge of an unused petri dish. Glass and metal spreaders and inoculating loops can be sterilized in a beaker of 70% ethyl or isopropyl alcohol.

jominy hardness test|jominy steel hardenability test